Quality and control

Comprehensive and technologically complete quality control over the whole process:

Entry control:

- spectral analysis of input raw materials in accordance with internal supply conditions

- visual control of incoming raw materials in accordance with internal delivery conditions

- careful selection and evaluation of suppliers of raw materials

Process control:

- Temperature monitoring

- Measurement of C-equivalents

- Control of melt with ATAS

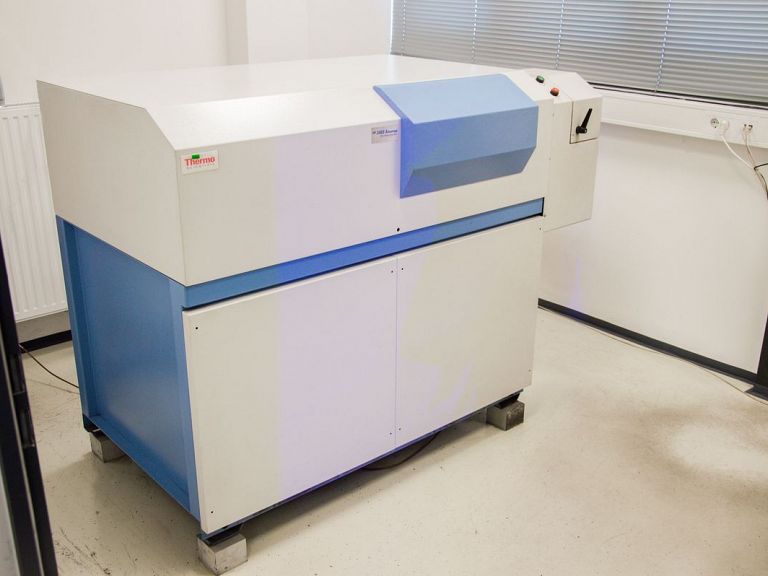

- Spectral chemical analysis with ARL 4360

- Control of the microstructure of produced materials with ZEISS AxioImager A2m microscope with AxioVision application for program recognition and analysis of the microstructure

- Hardness control with PROCEQ EQUOTIP 3 for several different areas (HLD, HRC, HV, and HB)

- Full implementation of NDT and DT inspections:

-

- DT inspections:

- Tensile test with 0-250 kN testing using the ZWICK Roel Z250Red tensile machine

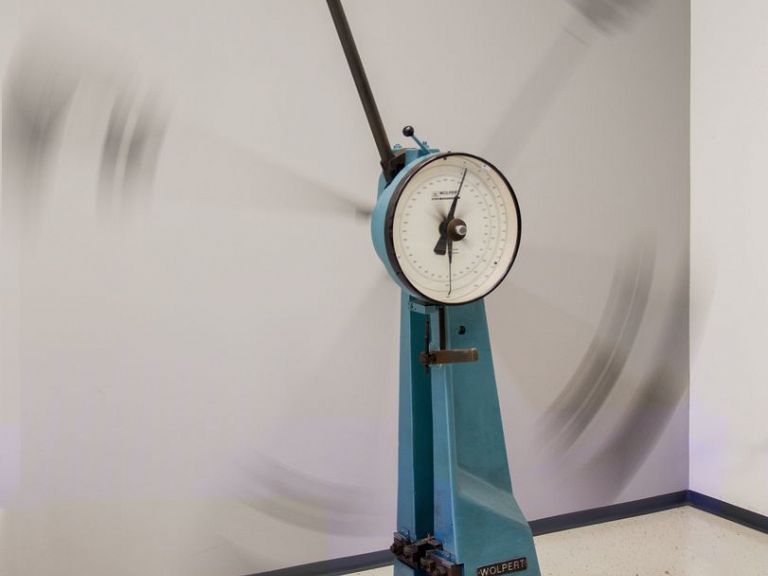

- Charpy test with the V-specimen from +20°C to max -40°C

- NDT inspections:

- Visual inspections (VT1+VT2 Level)

- Penetrant examinations (PT1+PT2 Level)

- Ultrasonic examinations (UT1 Level)

- Optional:

- Magnetic testing – external

- Radiographic testing – external

- Dimensions control in 2D and 3D manner:

- GOM ATOS COMPACT Scan 5M

- FARO Arm Platinum

- Possibility of reverse-engineering with Geomagic software package

- DT inspections:

Final control

- Packaging control

- Preparation of the final documentation for all completed procedures including 3.1 certificate of conformity of material according to EN standards and customer specifications.