Quality

Quality control means process and measurement control to demonstrate the compliance with input requirements, semi-finished products and products, as well as the certification of meeting requirements for processes and the customer. The purpose of the process is also to allow the delivery of only quality products to the customer.

- Entry control

- Visual control of entry products in accordance with internal supply conditions

- Careful selection and evaluation of suppliers

- 100% traceability: traceability of products/services is determined through the barcode system with procedures and instructions over the whole production process.

- Final quality control:

- Dimensional control

- 3D measurements (Carl-Zeiss Contura G2)

- 3D scanning (ATOS CompactScan 5M)

- NDT methods (VT, MT, PT, UT)

- Non-destructive material testing

Non-destructive material testing is carried out in an internal laboratory. Our staff is qualified in accordance with EN ISO 9712 for carrying out the non-destructive methods.

- Special quality control:

- Hardness testing

- Color thickness control

- Color adhesion control

- Gloss control

- UT ultrasonic testing

- MT magnetic testing

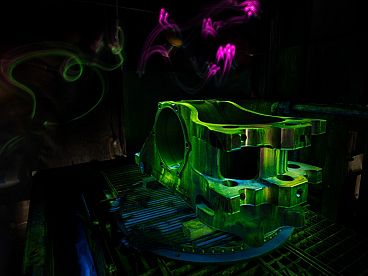

- VT visual testing

- PT penetrant testing

- Measurement of the air resistance of brake discs at rotation: with our own developed device, it is possible to measure how much power it takes to rotate an individual disc at desired turns. Due to the increasing efficiency required, the data of rotating air resistance is an increasingly important parameter in determining the quality of the brake disc.