Automatic moulding line – AFL and sand preparation

- Automatic moulding line and pouring machine (HWS) with dimensions 1270x1070x(400+(400+50)) mm and speed up to 80 moulds/h or 45 seconds per cycle.

- Moulding machine with rotary table and Seiatsu moulding system (pulse + batch mould curing).

- Daily production of 760 moulds and capacity of 1.600 tonnes per month.

- Sophisticated marking system to ensure traceability of castings per mould

- Casting line for 8 moulds with automatic casting machine with a melt capacity of two tonnes.

- Automatic melt-jetting system and temperature measurement system during casting.

- Cooling tower with a capacity of 282 moulds and a cooling time of 3-5 hours, with the possibility of adjusting the cooling time in stages.

Sand preparation

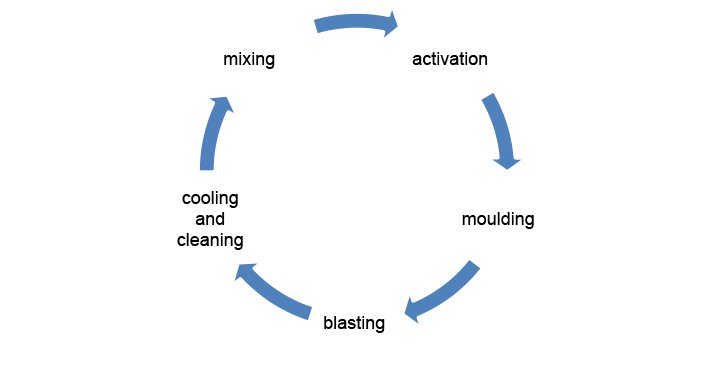

- Circular bentonite sand preparation process: sand preparation in a vacuum-turbine mixer with a capacity of 7 tonnes, which ensures the most constant properties of the bentonite sand mixtures regardless of the ambient temperature.

- Automatic quality control of the sand mix (per mixer) and automatic correction of the dosing of additives into the mixer.