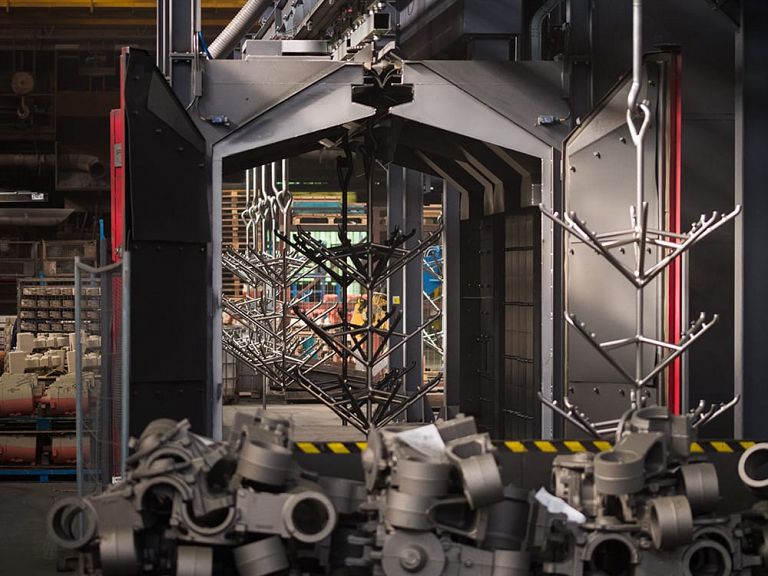

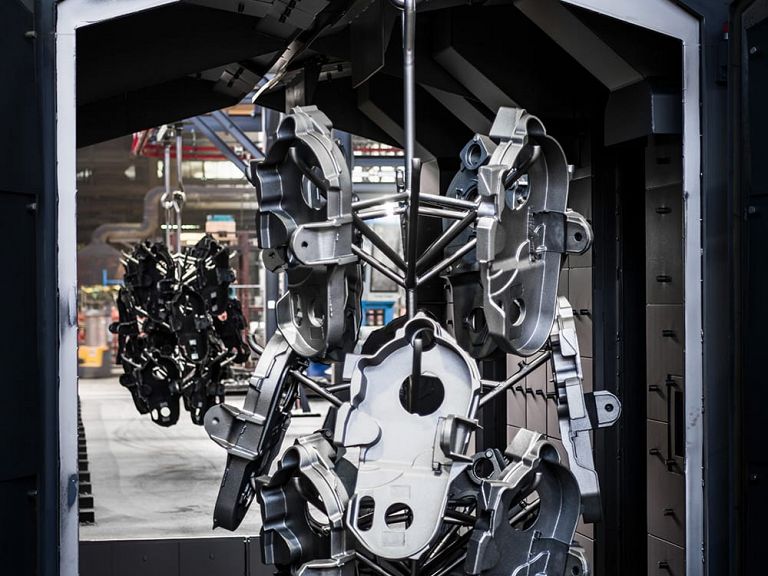

Cleaning plant and castings painting area

- Automatic shake-out and cooling conveyor belt, collection of clusters

- The castings are separated from the pouring system with special breaking wedges

- Automatic sandblasting machines for blasting the castings

- Mechanical and manual grinding: 2 CNC grinding machines (MAUS 600 and LIANCO)

- Robotic edge milling arm-KUKA

- Automatic line for painting the castings by dipping in water-based paints

- Painting capacity 400 tons per month and max dimension of casting: 1100x900x500; 180 kg